SELF-ASSEMBLY PROCESS PLANT (SAPP)

DIDAKTIK Self-Assembly Process Plant (SAPP) offers flexibility in the various designs which constructed in the form of modular process skid. Modular process skid has become more prevalent as a drive to support new construction or developments for rapid execution of process plants. Different types of modular unit are available to provide more experience in hands-on training especially for actual working environment in the industry.

PRODUCTS OF SELF-ASSEMBLY PROCESS PLANT (SAPP)| PRODUCT CODE | PRODUCT NAME |

|---|---|

| MPC-01-B01 | BATCH PROCESS MODULAR PROCESS CONTROL |

| MPC-01-C01 | LIQUID LEVEL MODULAR PROCESS CONTROL |

| MPC-01-C02 | LIQUID FLOW RATIO MODULAR PROCESS CONTROL |

| MPC-01-C03 | LIQUID TEMPERATURE MODULAR PROCESS CONTROL |

| MPC-01-C06 | LIQUID LEVEL FLOW MODULAR PROCESS CONTROL |

| MPC-01-C09 | LIQUID LEVEL FLOW TEMPERATURE MODULAR PROCESS CONTROL |

| MPC-02-C03 | AIR TEMPERATURE MODULAR PROCESS CONTROL |

| MPC-02-C04 | AIR PRESSURE MODULAR PROCESS CONTROL |

| MPC-03-C05 | CHEMICAL ANALYTICAL MODULAR PROCESS CONTROL |

For further inquiries, please email us at info@dewsb.com

DESCRIPTION:

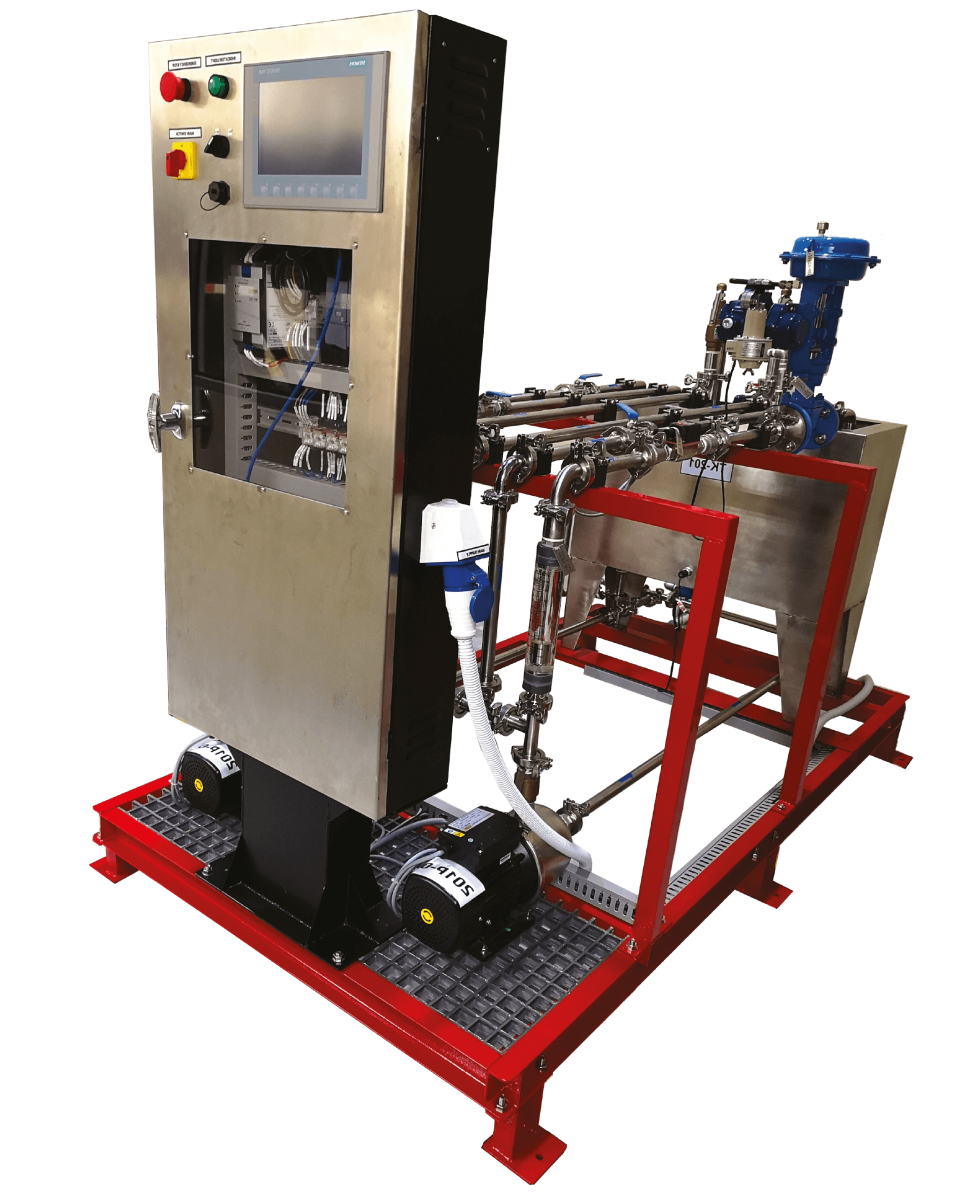

MPC-01-B01 is a scale-down industrial Standard “Self Assembly Process Plant” or SAPP based on actual industrial physical Batch Blending Process Plant. This process plant is developed in modular structure for easy assemble and dismantle. This SAPP is shipped as a fixed process plant , however it can be dismantle easily as the “Self Assembly Process Plant” (SAPP). All instruments, sensors, local control panel with castor wheels for easy re-allocation, assembly and dismantling works, controller are designed in a modular structure mounted with the connecting accessories for easy installation.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The DIDAKTIK MPC-01-C01 Liquid Level Modular Process Control exposes trainees to the fundamental of level measurement, instrumentation and process control which commonly found in oil & gas and petrochemical industries. The MPC-01-C01 features a stainless steel tank equipped with a range of sensing and transmitting technologies. The tank is equipped with differential pressure sensors that monitor changes in water level and transmit feedback to the automated control system in real-time. The trainees use a PID control system to regulate liquid level which is adjusted using the tank’s feed water pump and outlet valve.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The MPC-01-C02 Liquid Flow Ratio Modular Process Control Trainer plant provides hands-on training of the industrial flow control principles, processes and theory required to stabilize liquid flow through multiple processes in a distribution network. The training components contain the necessary instrumental equipment and control systems to simulate the liquid flow processes of a real world process plant using water as a risk-free liquid. The self-assembly design actively instructs the tasks and requirements related to flow process calibration, configuration, maintenance and troubleshooting relevant to real-industrial situations.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The DIDAKTIK MPC-01-C03 Liquid Temperature Modular Process Control exposes trainees to the shell and tube heat exchange process common in petrochemical and power industries. Trainees are able to study the shell and tube designs that create heat transfer between two liquids. In this model, tubes are enclosed inside a cylindrical shell, allowing one substance to run through the tubes and another substance to run around the tubes. Heat transfer occurs from shell to tube or vice versa. The fluid with the higher temperature conducts heat through the tube walls to the other liquid that has lower temperature.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The DIDAKTIK MPC-01-C06 Liquid Level Flow Modular Process Control Trainer exposes trainees to the fundamental of level and flow measurement, instrumentation and process control which commonly found in oil & gas and petrochemical industries. It also demonstrates the advance application of the cascade control that can improve the feedback single loop control application.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The DIDAKTIK MPC-01-C09 Liquid Level, Flow & Temperature Modular Process Control focuses learning on three common key parameters common to many industrial, scientific, and commercial process plants; liquid level, liquid flow and liquid temperature. In this model, sensors for flow meters, level transmitters are attached to a level tank and pipes to capture and transmit data to a PID control system. Trainees can use the PID parameters to maintain liquid level, flow and temperature.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Equipment

3. Fundamental to Process Control

4. Hands-On Training Activity

DESCRIPTION:

The MPC-02-C03 Air Temperature Modular Process Control Trainer plant is designed to illustrate the concept of industrial gas control principles, processes and theory. Trainees discover how gas temperature can impact operations and how to manipulate it within a process plant in a controlled environment using air instead of hazardous gases as a safe medium.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Control

3. Hands-On Training Activity

DESCRIPTION:

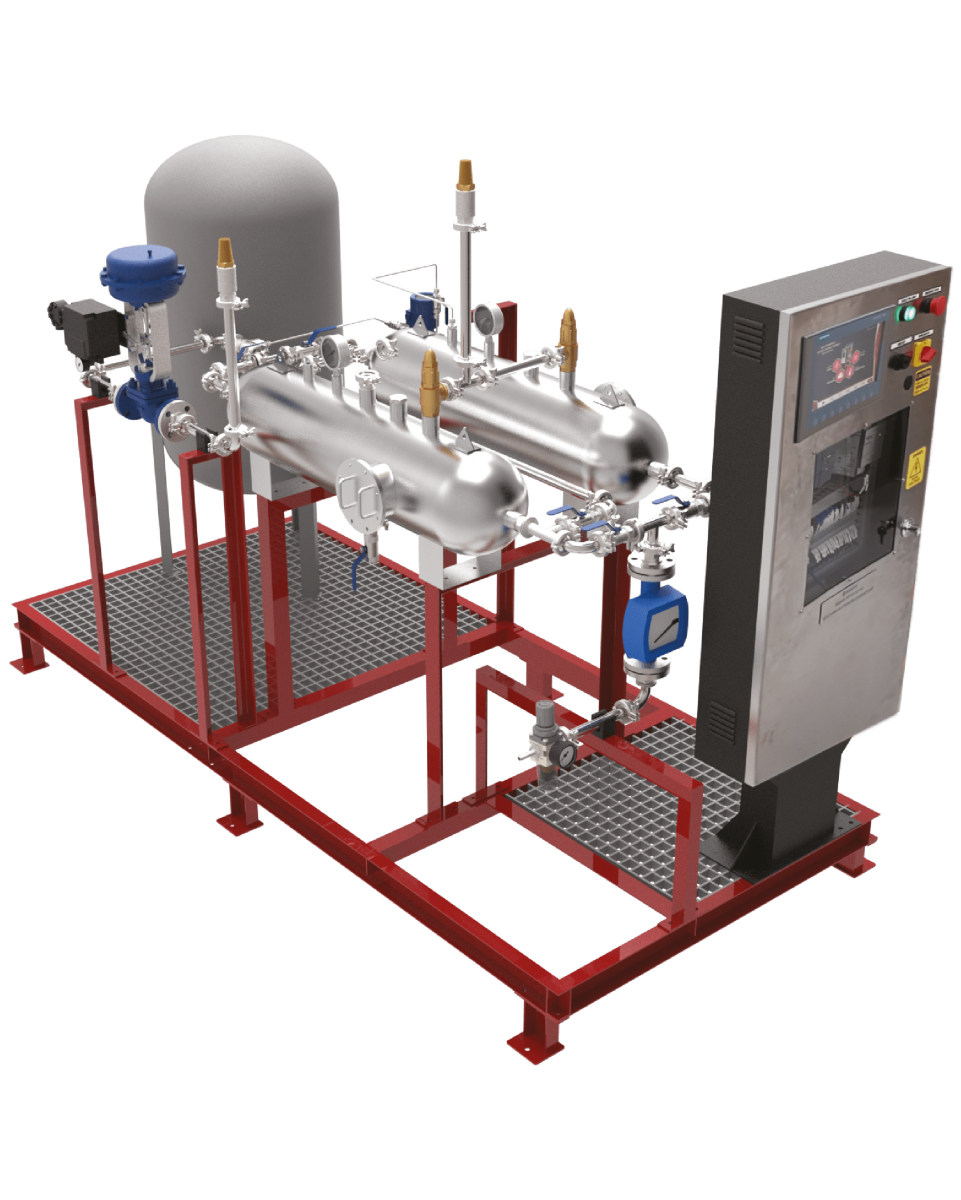

The DIDAKTIK MPC-02-C04 Air Pressure Modular Process Control Trainer is designed to illustrate the concept of industrial air control principles, processes and theory. Trainees able to discover the significant of air pressure in the process operation and how to manipulate it within a process plant. Using the MPC-02-C04, trainees will focus on reaching the correct air pressure while compensating for changing to single or parallel flow. The model uses a pneumatic control valve to maintain proper system pressure, enabling the trainees to study common issues with air pressure. Air pressure data is measured with gauges and communicated by pressure transmitters to a controller. The panel mounted control system allows the trainees to control air pressure based on overshoot and deviations from the desired ranges.

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Control

3. Hands-On Training Activity

DESCRIPTION:

The MPC-03-C05 Chemical Analytical Modular Process Control provides trainees the exposure of principles in chemical analytical instrumentation, including pH, conductivity and dissolved oxygen measurements. The model demonstrates the common systems to real-world processes such as acid-alkali neutralization, oxidation-reduction reactions, conductivity and dissolved oxygen control, using Neural Network prediction for TDS (control using DCS only).

LEARNING OUTCOME:

1. Fundamental to Instrumentation & Measurement

2. Fundamental to Process Control

3. Hands-On Training Activity